QUALITY

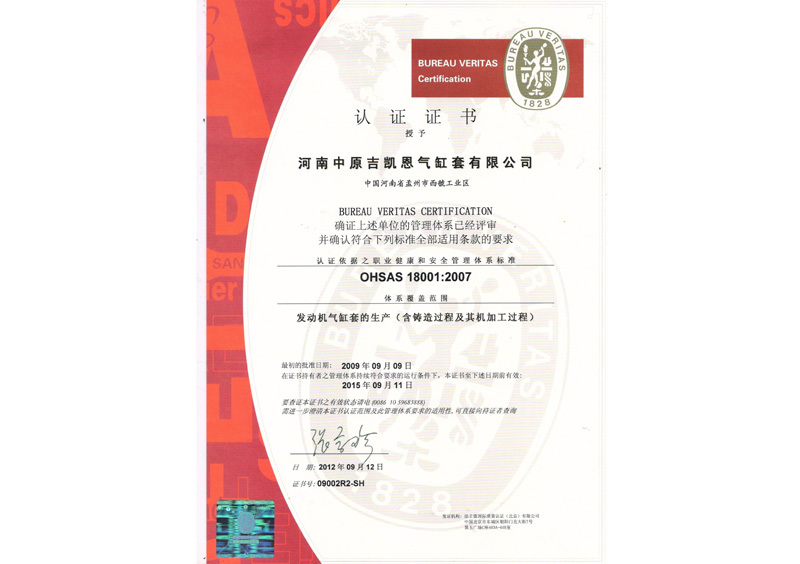

Quality System Certification

IATF16949

OHSAS 18001:2007

IOS/TS 16949:2009

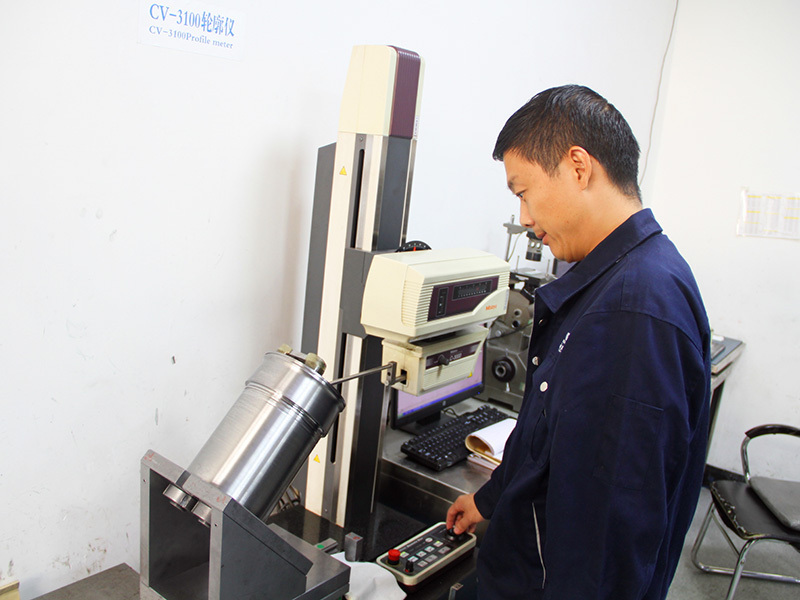

We have state-of-the-art testing& measurement facilities

Accurately grasp market demand, through strict selection of materials and exquisite craftsmanship

I want to consultStandardized product quality management

Total Quality Management

With total employee involvement, focusing on quality, GKNZ is committed to ensuring that all staffs’ work in strict accordance with international quality standards.

Continuous Improvement

We abide faithfully by the concept of “Prevention based, continuous improvement, consistent quality, customer satisfaction”

Modern QM Toolbox

Applying most cogent method quality management tools : 5 QM tools(SPC, FMEA, MSA, PPAP, APQP), POKEYOKE, 8D, 5 Why analysis, layered audit, lean production management, etc.

Traceability System

Green card system and barcode system are used to realize a product lifecycle traceability from raw material supply to end-customer service.

Cooperative clients

Raw material supply

Incoming inspection shall be carried out for incoming materials, the quality shall be strictly controlled, the identification shall be clear, and the storage and use shall be standardized.

Melting

coreless induction melting furnace

Installed smelting capacity 15 t/h

Customized material melting

quick analysis in front of furnace

Quality monitoring of molten iron in high frequency secondary holding furnace

Casting

Centrifugal casting process-single solidification under centrifugal force

Horizontal Centrifugal Casting Process-High Length and Diameter Ratio

Centrifugal casting process machine developed by GKN engineer FW Stokes1917 years: long-term experience

GKN has independent intellectual property rights of centrifugal casting equipment

Manipulator-assisted blanking to improve production efficiency

Machining

Temperature control workshop

Lean production culture

MES Manufacturing System

Digital efficient intelligent production line

Food grade constant temperature processing media filtration system

Cleaning

Multiple ultrasonic cleaning

Meet the requirements of ISO16232 standards (impurity quantity and quality analysis)

Quality Controls

The company has advanced quality inspection equipment: from basic inspection equipment such as carbon and sulfur analyzer, spectrometer, hardness tester, profilometer, cylindricity meter, microscope, etc. to ultra-advanced product inspection equipment such as online reticulated roughness detector, online automatic visual inspection system, full-automatic table thickness grouping equipment, online SPC data collection system, full-automatic inspection station, etc., which ensure the reliability and stability of quality in the whole process from raw material input to product output.

Leave a Message

We will contact you within one working day. Please pay attention to your email.